• Mould height: 50 - 150 mm

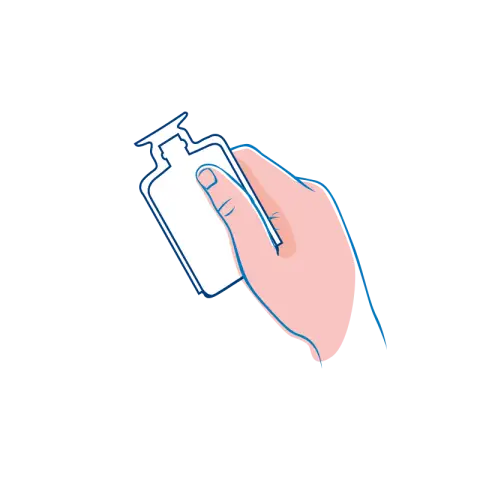

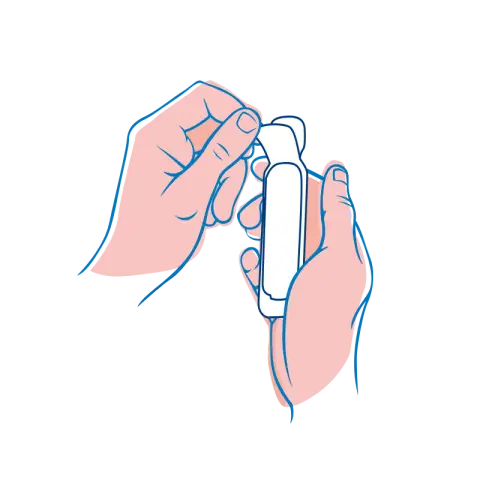

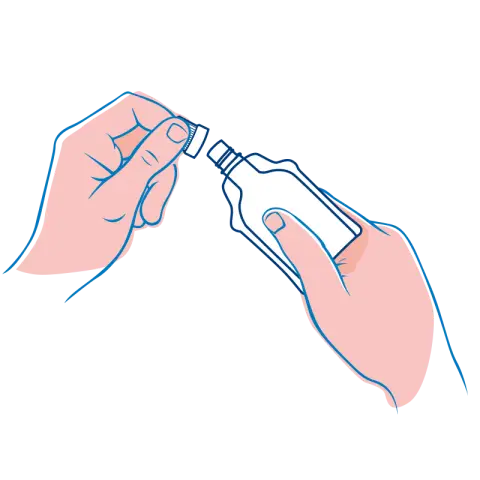

• Single or double dosing unit for liquid and semi-dense products

• High precision cutting unit

• Possibility to use special barrier materials such as EVOH or PVDC to extend product shelf-life

• Reels width range: between 100 – 300 mm

• Reel holding unit with 2 powered shafts and a buffering unit that allows the change-over of the plastic reel without stopping the machine

• Filling range: 1 – 250 ml

• Number of cycles/min.: Up to 35

• Thermoforming mould area TF X5 260 260 mm (w) X 120-150 mm (h)

• Thermoforming mould area TF X5 300 300 mm (w) X 120-150 mm (h)

• Overall Dimensions: 6650 mm X 3250 mm X 2500 mm (h)

• Total machine weight: 3.500,00 kg

• Air consumption: 1100 Nl/min – 6 bar

• Power consumption TF X5 260 30 kW / 50 A (mould width 260 mm)

• Power consumption TF X5 300 32 kW / 60 A (mould width 300 mm)

• Plastic film thickness: 250 - 480 µm