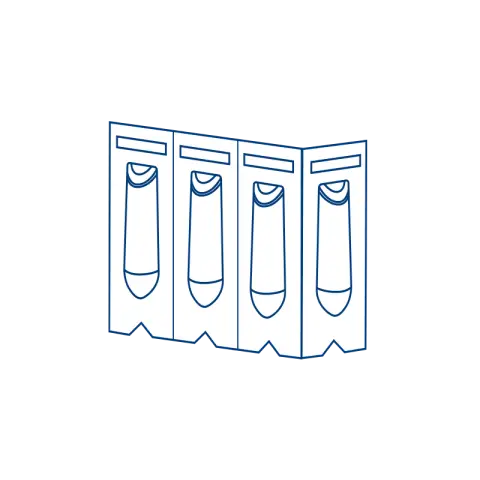

• Dosing unit in AISI 316L.

• Special off-line dosing to allow the operator to check the accuracy of the dosing (upon request).

• No top trimming operations required.

• Easy machine access and maintenance operations thanks to its balcony structure.

• Quick tooling change-over from PVC/PE shape to ALU/PE shape and vice-versa.

• TIP 106 unit for the connection to a cartoning machine.

• Filling range: 0,2 – 4 ml

• Output production/h: Up to 35.000 (equipped with three cooling tunnels)

• Thermoforming mould area: 210 mm (w) - 80 mm (h)

• Overall dimensions: 6750 mm x 1500mm x 2300mm

• Total machine weight: 4.690,00 kg

• Air consumption: 350 Nl/min

• Power consumption 26-33 kW

• Film thickness (PVC/PE) 100 - 150 μm

• Film thickness (ALU/PE) 75 - 150 μm

• The machine is equipped with a peristaltic pump and product level control inside the tank. Upon request the machine can also be equipped with a print registration unit, a dry coding device, PVC/PE micro-holes detection system and a special patented system to detect micro-holes also when using ALU material.